The 2002 Jeep Grand Cherokee (WJ model) is a legend, known for its blend of on-road comfort and off-road capability. A key contributor to this versatility is its suspension system. Over time, however, these parts can wear down, impacting ride quality, handling, and safety. This comprehensive guide will delve into the various suspension components of the 2002 Grand Cherokee, exploring their function, common issues, replacement options, and crucial considerations for keeping your WJ running smoothly.

Introduction: Understanding the Importance of Your 2002 Jeep Grand Cherokee Suspension

Navigating the Road: A Comprehensive Guide to 2002 Jeep Grand Cherokee Suspension Parts

The suspension system is the unsung hero of your 2002 Jeep Grand Cherokee. It's responsible for absorbing bumps and vibrations, maintaining tire contact with the road, and providing stable handling. A well-maintained suspension ensures a comfortable ride, predictable steering, and optimal braking performance. Neglecting suspension issues can lead to a bumpy ride, poor handling, premature tire wear, and even dangerous driving conditions. For a vehicle that's now over two decades old, understanding and maintaining its suspension is critical for its longevity and your safety.

Section 1: The Anatomy of the 2002 Grand Cherokee Suspension System

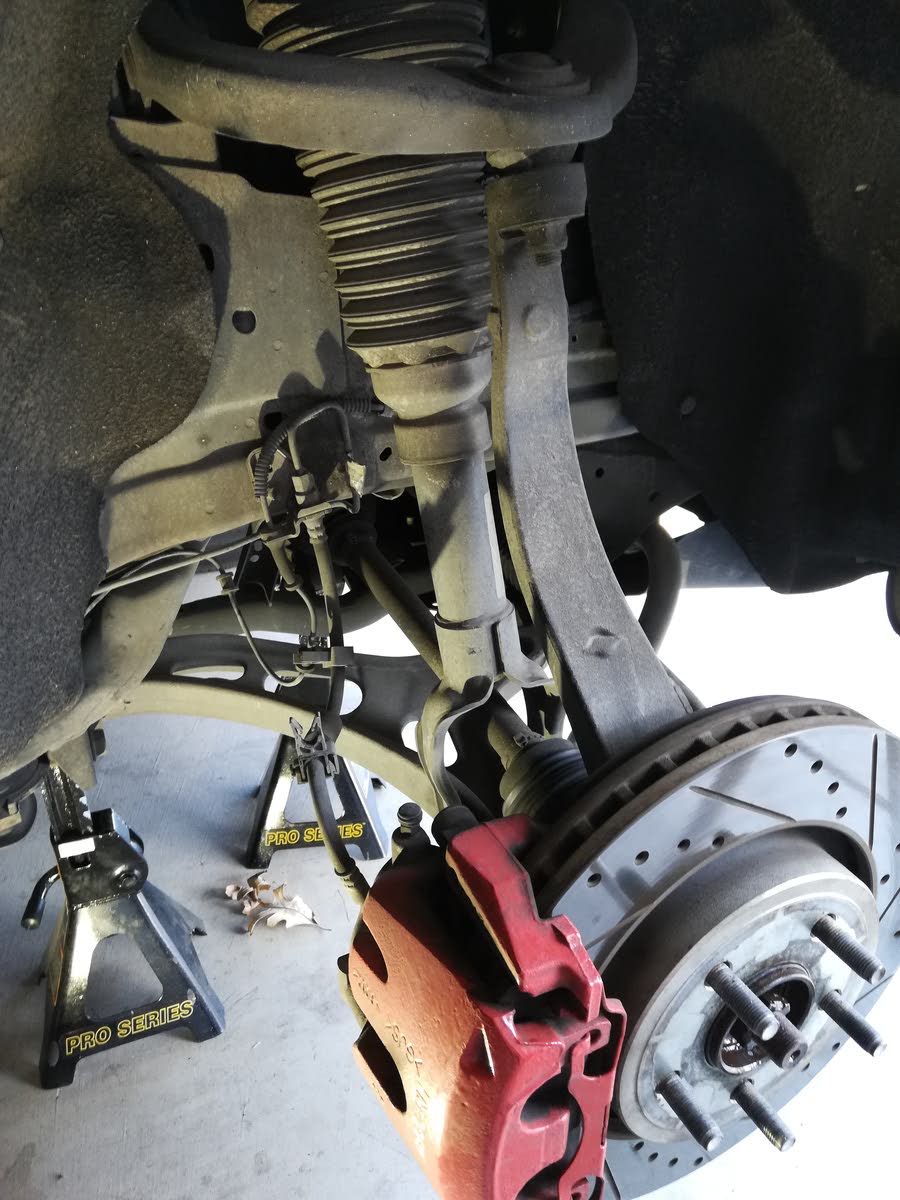

The 2002 Grand Cherokee's suspension system, depending on the model and options package, could include variations, but generally consists of the following key components:

- Shocks/Struts: These hydraulic dampers control the movement of the springs, preventing excessive bouncing and ensuring a smoother ride. They convert kinetic energy into heat.

- Springs (Coil Springs): Located at each wheel, springs absorb impacts and support the vehicle's weight. They determine the ride height and contribute to overall handling.

- Control Arms (Upper and Lower): These arms connect the wheel hub to the vehicle's frame, allowing for vertical movement while maintaining proper wheel alignment. Bushings within the control arms provide flexibility and absorb vibrations.

- Track Bar (Panhard Rod): This bar connects the rear axle to the frame and prevents lateral movement of the axle. It's particularly important for maintaining stability.

- Sway Bar (Anti-Roll Bar): The sway bar connects the left and right sides of the suspension, reducing body roll during cornering and improving stability. Sway bar links connect the sway bar to the suspension.

- Bushings: These rubber or polyurethane components cushion and isolate various suspension parts, reducing noise, vibration, and harshness (NVH). They are found in control arms, sway bar links, and track bars.

- Ball Joints: Ball joints allow for pivoting movement between the control arms and the steering knuckles, enabling steering and suspension articulation.

- Steering Components (Tie Rods, Drag Link): While technically part of the steering system, these components work closely with the suspension to control the direction of the wheels.

Section 2: Common Suspension Problems in the 2002 Grand Cherokee

Age and mileage take their toll. Here are some of the most frequent suspension issues encountered in the 2002 Grand Cherokee:

- Worn Shocks/Struts: Symptoms include excessive bouncing, nose-diving during braking, poor handling, and fluid leaks.

- Sagging Springs: Sagging springs result in a lower ride height, reduced ground clearance, and a compromised ride quality.

- Worn Control Arm Bushings: Cracked or worn bushings cause clunking noises, vibrations, and imprecise steering.

- Loose or Worn Ball Joints: Symptoms include popping or clicking noises, loose steering, and uneven tire wear.

- Damaged Track Bar Bushings: This leads to "death wobble" (a violent shaking of the front end), wandering steering, and poor stability.

- Broken Sway Bar Links: Broken links result in excessive body roll during cornering and a clunking noise.

- Steering Issues: Steering issues can be caused by many suspension related parts.

Section 3: Diagnosing Suspension Issues: Listen, Look, and Feel

Before replacing any parts, it's crucial to accurately diagnose the problem. Here's a simple diagnostic process:

- Listen: Pay attention to any unusual noises, such as clunking, popping, squeaking, or grinding sounds, especially when going over bumps or turning.

- Look: Visually inspect the suspension components for signs of wear and tear, such as cracked bushings, leaking shocks, sagging springs, and damaged ball joint boots. Also, check your tire wear patterns. Uneven wear can indicate suspension problems.

- Feel: Bounce each corner of the vehicle. If the vehicle continues to bounce excessively after you release it, the shocks/struts may be worn. Also, check for play in the steering wheel. Excessive play can indicate worn steering components or ball joints.

Section 4: Replacing Suspension Parts: A DIY Guide (with Caveats)

Replacing suspension parts can be a rewarding DIY project, but it requires mechanical aptitude, the right tools, and a healthy dose of caution. If you're not comfortable working on your vehicle, it's best to consult a qualified mechanic.

Tools You'll Need:

- Jack and Jack Stands (essential for safety)

- Wheel Chocks

- Socket Set (metric)

- Wrench Set (metric)

- Torque Wrench

- Ball Joint Separator (pickle fork or ball joint press)

- Spring Compressor (for replacing struts)

- Penetrating Oil

- Hammer

- Pry Bar

- Alignment Tools (if adjusting alignment)

General Steps (Specific steps will vary depending on the component):

- Safety First: Park the vehicle on a level surface, engage the parking brake, and chock the rear wheels.

- Loosen Lug Nuts: Loosen the lug nuts on the wheel you'll be working on.

- Jack Up the Vehicle: Raise the vehicle and securely support it with jack stands. Never work under a vehicle supported only by a jack.

- Remove the Wheel: Remove the lug nuts and the wheel.

- Disconnect Components: Disconnect any components that need to be removed to access the part you're replacing (e.g., brake lines, ABS sensors).

- Remove the Old Part: Use the appropriate tools to remove the worn part. Penetrating oil can be helpful for loosening stubborn bolts.

- Install the New Part: Install the new part, ensuring it's properly aligned and torqued to the manufacturer's specifications.

- Reconnect Components: Reconnect any components you disconnected earlier.

- Reinstall the Wheel: Reinstall the wheel and tighten the lug nuts.

- Lower the Vehicle: Lower the vehicle to the ground and torque the lug nuts to the proper specification.

- Repeat: Repeat the process for the other side of the vehicle if necessary.

- Get an Alignment: After replacing any suspension components, especially those affecting steering geometry (e.g., control arms, ball joints, tie rod ends), it's crucial to get a professional wheel alignment.

Important Considerations:

- Torque Specifications: Always torque bolts to the manufacturer's specifications. Over-torquing can damage components, while under-torquing can lead to loosening and failure.

- Penetrating Oil: Use penetrating oil liberally to loosen rusted bolts and nuts.

- Safety Glasses: Wear safety glasses to protect your eyes from debris.

- Spring Compressor: Be extremely careful when using a spring compressor. Improper use can lead to serious injury.

- Alignment: A proper wheel alignment is essential after replacing suspension components to ensure optimal handling, tire wear, and fuel efficiency.

- Rust: The age of the vehicle means that rust will be present on many of the suspension components. Budget time and tools to deal with rusty bolts.

Section 5: Choosing the Right Suspension Parts: Quality Matters

When replacing suspension parts, it's tempting to opt for the cheapest option. However, quality matters. Investing in reputable brands and durable materials will ensure longer-lasting performance and improved safety.

- OEM (Original Equipment Manufacturer) Parts: These are the same parts that were originally installed on your vehicle. They offer guaranteed fit and performance but can be more expensive.

- Aftermarket Parts: Aftermarket parts offer a wide range of options, from budget-friendly replacements to high-performance upgrades. Research brands carefully and read reviews before making a purchase.

- Lift Kits: If you're looking to increase ground clearance and off-road capability, consider a lift kit. However, be aware that lifting your vehicle can affect handling and may require modifications to other systems.

Section 6: Suspension Upgrades for Enhanced Performance

For those seeking to improve their 2002 Grand Cherokee's performance, several suspension upgrades are available:

- Performance Shocks/Struts: Upgraded shocks and struts can provide better damping and handling, especially for off-road driving or spirited on-road driving.

- Heavy-Duty Springs: Heavy-duty springs can improve load-carrying capacity and reduce sagging, especially if you frequently tow or carry heavy loads.

- Polyurethane Bushings: Polyurethane bushings are more durable and offer less flex than rubber bushings, resulting in improved handling and responsiveness.

- Adjustable Control Arms: Adjustable control arms allow you to fine-tune your suspension geometry and correct alignment issues after lifting your vehicle.

- Sway Bar Upgrades: Larger or adjustable sway bars can further reduce body roll and improve handling.

Section 7: Maintenance Tips for a Long-Lasting Suspension

Proper maintenance can significantly extend the life of your suspension system:

- Regular Inspections: Inspect your suspension components regularly for signs of wear and tear.

- Grease Fittings: Lubricate any grease fittings on the suspension components according to the manufacturer's recommendations.

- Avoid Overloading: Avoid overloading your vehicle, as this can put excessive strain on the suspension.

- Drive Carefully: Avoid driving aggressively over rough terrain or potholes.

- Alignment Checks: Have your wheel alignment checked periodically, especially after hitting a large pothole or curb.

Section 8: Price Table for 2002 Jeep Grand Cherokee Suspension Parts

| Part Description | Brand (Example) | Approximate Price (USD) | Notes |

|---|---|---|---|

| Front Shock Absorber | Monroe | $40 - $80 each | Price varies based on quality and features. |

| Rear Shock Absorber | Bilstein | $60 - $120 each | Higher-end brands offer improved performance. |

| Front Coil Springs (Pair) | Moog | $80 - $150 pair | Price varies based on spring rate and lift height. |

| Rear Coil Springs (Pair) | Crown Automotive | $70 - $130 pair | Consider heavy-duty springs if you frequently tow or carry heavy loads. |

| Upper Control Arm (Front) | Mevotech | $50 - $100 each | Includes ball joint and bushings. |

| Lower Control Arm (Front) | Dorman | $70 - $150 each | Includes ball joint and bushings. |

| Track Bar (Rear) | JKS | $80 - $200 | Adjustable track bars are available for lifted vehicles. |

| Sway Bar Link Kit (Front) | Energy Suspension | $20 - $50 kit | Polyurethane bushings offer improved durability. |

| Sway Bar Link Kit (Rear) | ACDelco | $20 - $50 kit | |

| Ball Joint (Upper/Lower) | Moog | $20 - $50 each | Ensure compatibility with your control arms. |

| Complete Strut Assembly (Front) | KYB | $150 - $300 each | Includes strut, spring, and mount for easier installation. |

| Steering Stabilizer | Rancho | $50 - $100 | Reduces steering wobble and improves handling. |

Note: Prices are approximate and can vary depending on the retailer, brand, and specific vehicle configuration. It's always recommended to compare prices and read reviews before making a purchase.

Conclusion: Keeping Your 2002 Grand Cherokee Rolling Smoothly

Maintaining the suspension of your 2002 Jeep Grand Cherokee is essential for a comfortable ride, safe handling, and overall vehicle longevity. By understanding the components, diagnosing issues early, and choosing quality replacement parts, you can keep your WJ rolling smoothly for years to come. Whether you're a seasoned DIYer or prefer to leave it to the professionals, prioritizing suspension maintenance is an investment in your safety and enjoyment of your Jeep. Don't neglect the unsung hero of your vehicle – your suspension!

Frequently Asked Questions (FAQ)

Q: How often should I replace my shocks/struts?

A: As a general guideline, shocks and struts should be replaced every 50,000 to 75,000 miles, or sooner if you notice signs of wear.

Q: Can I mix and match brands of suspension parts?

A: While it's generally not recommended, you can mix brands. However, ensure that all parts are compatible with your vehicle and that you're not mixing significantly different performance levels (e.g., a high-performance shock with a standard spring).

Q: Do I need a wheel alignment after replacing shocks/struts?

A: It's always a good idea to get a wheel alignment after replacing shocks or struts, as the new components can affect your vehicle's alignment.

Q: What is "death wobble" and how do I fix it?

A: "Death wobble" is a violent shaking of the front end that can occur in Jeeps, often caused by worn track bar bushings, loose steering components, or improper alignment. Addressing these issues is crucial for fixing the problem.

Q: Can I lift my 2002 Grand Cherokee myself?

A: Installing a lift kit can be a DIY project, but it requires significant mechanical knowledge and the right tools. If you're not comfortable with the process, it's best to have it installed by a professional.

Q: What are the benefits of upgrading to polyurethane bushings?

A: Polyurethane bushings are more durable, offer less flex, and provide improved handling and responsiveness compared to rubber bushings. However, they can also transmit more noise and vibration.